Sustainable Spotlight: Re/Marmor

Re/Marmor

Reimagine Marble

What is the material’s composition?

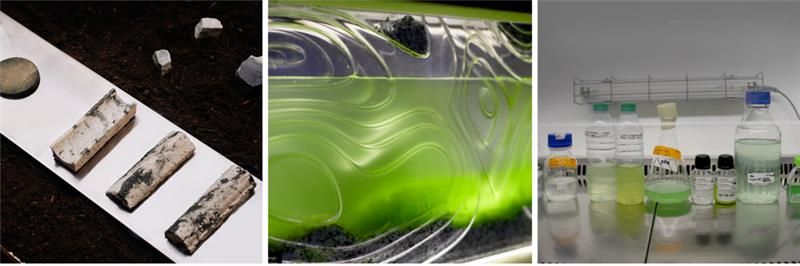

The concept primarily involves using ‘marble waste’ as a raw material in conjunction with a biological composite derived from Cyanobacteria.

- Marble Dust: This is generated from the marble manufacturing process.

- Marble Aggregates: These consist of offcuts from marble manufacturing and quarrying, which are

crushed or ground into fine particles.

- Cyanobacteria: This microorganism generates calcium carbonate, the main component of marble stone.

How did you create the concept for this product?

Re/Marmor aims to create a sustainable approach to marble production by utilizing the 53% waste generated from the current manufacturing process. This waste can be used as a raw material, allowing manufacturers to invest in their own by products. Additionally, using cyanobacteria, which can produce calcium carbonate, I am exploring the creation of marble through scientific research. While technology can generate marble patterns, the hand-made Scagliola technique offers unique value through the co-creation of materials between humans and nature.

How long did it take you to figure out how to make this material? Was there a lot of trial and error?

The experimentation phase lasted roughly six months, during which I worked with microorganisms based on scientific literature, incorporating some twists and substitutions. As expected, when developing something new, this process was fraught with errors, particularly given that biological processes like these are still being studied and not fully understood. Please note that this bio-marble containing cyanobacteria is still in the development phase. I utilized the CSM Grow lab for this project, which has limited lab access. With full-time access to experimentation, the process could be expedited.

What is the lifespan of this product?

The material has not yet undergone lifespan testing, but it should be durable as long as it is not degraded by acidity, similar to natural marble stone. And because it doesn't require extraction from mountains, I think it is reasonable to dismantle it for short-term interior decoration since the material can be recycled to create new Re/Marmor. This recycling process involves incorporating additive colours derived from alternative sources, such as plants or bacteria, which makes Re/Marmor a circular material.

Where do you source your materials to make this product?

Once the product is marketable, raw waste can be sourced from quarries or any marble manufacturer. Cyanobacteria can be obtained from reputable laboratories to ensure the correct type is used. For this project, Cyanobacteria was supplied by Grow Lab at Central Saint Martins. The marble waste was collected from a London-based marble manufacturer for educational purposes. (The company requested that I do not disclose their name to avoid being overwhelmed with inquiries from students.)

What uses has this material currently got? What are its real-life applications?

As this material is still under development to enhance its rigidity, it can currently serve as a decorative element in various interior spaces. The goal is to replace conventional marble, with a significant focus on achieving fire resistance.

What uses do you see this material having in the future, and to what scale can this product be used?

In addition to the transition away from quarrying traditional marble, I see air purification as another significant application. Cyanobacteria thrive on carbon dioxide (CO2) and give out oxygen. Ideally, the quarries themselves could transform into hubs for producing this bio-marble, all while rejuvenating the land that has been affected by extraction.

What measures do you take to ensure that you are making this product in the most environmentally conscious way possible?

- Resource Management: I utilize what is generally considered waste, such as leftover marble fragments.

I also prioritize recycled or recyclable vessels and moulds wherever feasible. Additionally, I plan the use of all materials to maximize efficiency, for example, by strategically arranging wood while making mould to minimize waste.

- Energy Efficiency: I aim to harness natural energy whenever possible, such as using sunlight as a light source.

- Ethical Considerations: This is an ongoing debate for me. My initial objective was to create a living marble, thus avoiding harm to microorganisms. However, the current process unfortunately results in their death. Moving forward, I aspire to develop a marble that maintains living microorganisms as its next step.)

)

)